한국카본의 새로운 소식과 비디오를 확인해 보세요.

한국카본은 고속경화수지(4분/150℃)를 양산 전용으로 하는 에폭시 글라스 프리프레그를 개발했다. 따라서 프레스 방식을 사용하는 PCM(Preregory Compression Molding) 기술을 적용할 수 있습니다. 또한 이 재료는 시트 성형 방법을 사용하는 모든 구성 요소에 적합한 것으로 나타났습니다. 특히 UL-94 V0 등급으로 난연성이 필요한 EV 배터리 케이스 생산에 적합합니다. 구체적으로 배터리 커버는 물론 높은 기계적 특성이 요구되는 배터리 하단 트레이에도 적용할 수 있다. 또한 탄소 원단과 유사한 기계적 특성과 탄소 원단에 비해 저렴한 원료가 특징이다.

South Korea / UK / Germany, March 16th 2022

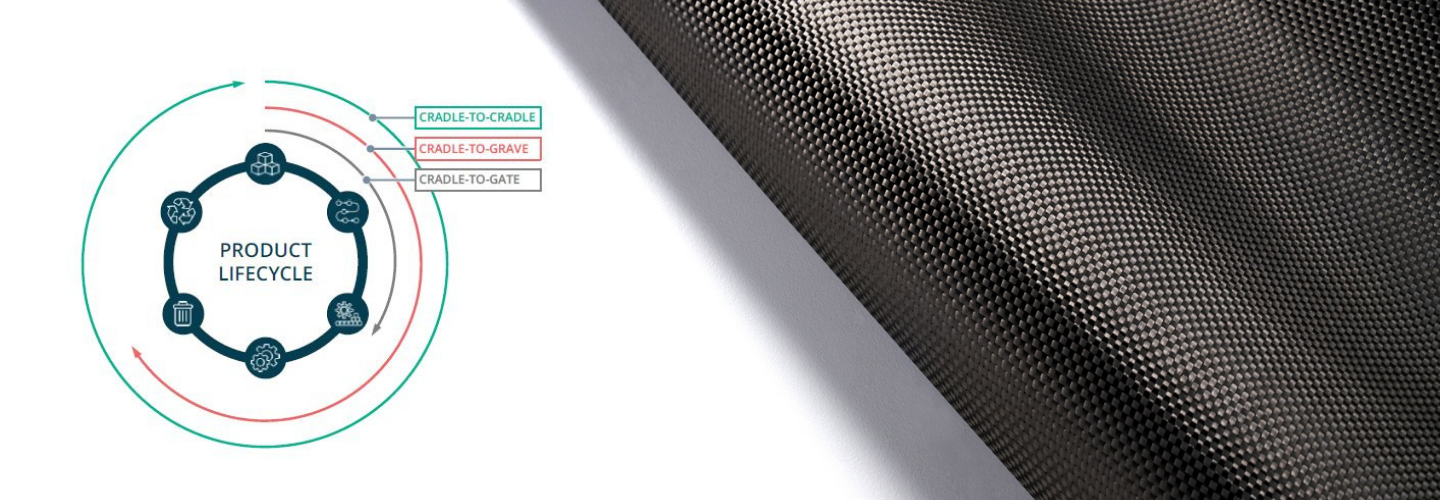

Ahead of most of its competitors, Hankuk Carbon announces today it has finished the first stage of life cycle assessment (LCA) for its carbon fiber prepreg, in order to quantify the CO₂ emissions of its materials and find solutions for a more sustainable future.

In various applications composite materials contribute to sustainability and reduce through-life carbon impact by enabling the manufacture of complex lightweight structural applications in cars, aircraft and wind-turbines, leading to longer life-cycles and less use of fossil fuels during the use phase. Upcoming recycling technologies will allow to use these materials to be effectively recovered for multiple life-cycles.

Critics can point out the higher embodied energy of carbon fibre without considering the end applications of composite materials. Efficient application designs utilising composites enable lower energy usage in the use phase and this is often significantly higher than the energy used in the manufacturing phase, especially if materials are recyclable. Hankuk Carbon has worked with Forward Engineering GmbH (Germany), a third-party expert consultant company who use the internationally recognised ISO 14040/44/67 standard as the baseline for their calculation, to conduct an overall first analysis of the carbon footprint of carbon-epoxy prepreg from cradle-to-gate. This gave Hankuk Carbon the opportunity to identify opportunities to improve sustainability in processing and to create an action plan to do so.

Looking ahead, Hankuk Carbon plans to conduct a more detailed LCA for its carbon fibre prepreg as well as liaise with its raw material suppliers and end customers to help appraise and reduce not only its own carbon footprint, but the overall footprint in its materials and applications. Furthermore, Hankuk Carbon is looking into forming strategic partnerships with carbon re-cycling companies to facilitate collaboration between its end customers across the supply chain to further reduce carbon footprint of composite components.

About Hankuk Carbon

Hankuk Carbon is the largest producer of composite intermediates in the South Korea. With over 35 years’ experience of manufacturing composite Prepregs and multi-functional laminated systems, Hankuk Carbon delivers a wide range of innovative, multi-functional ‘Composite, All at once’ solutions for Automotive, Aerospace, Energy, Shipbuilding, Construction, Sports and Defence industries.

Hankuk Composite UK has been part of the Hankuk Carbon Group since 2020 and represents the business across Europe, with applications engineering and sales support. The move comes as part of a commitment from Hankuk Carbon to strengthen links with automotive OEMs in Europe, and to develop deeper connections with sports, leisure and industrial markets.

About Forward Engineering

Forward Engineering (FE) is a Global Engineering and Consulting Firm based in Munich, Germany with offices and representation in Japan, China and the US, that specialize in holistic and sustainable product development employing the latest proven and emerging materials and manufacturing process technologies.